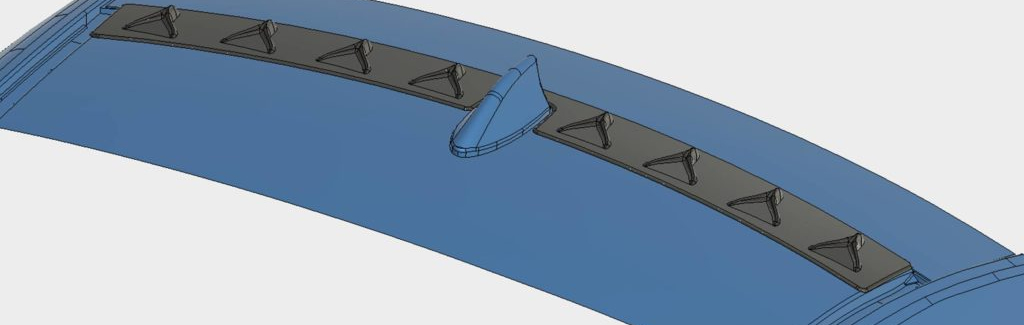

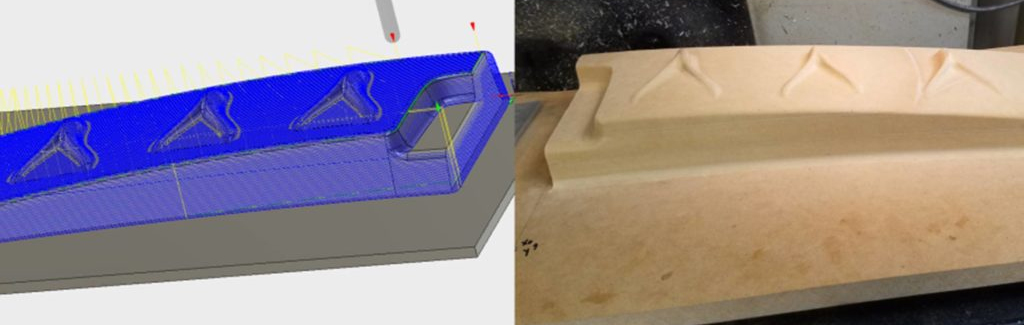

The first step in any product design process is to identify a market demand. As car enthusiasts and engineers, we are constantly striving to create new products and improve existing designs. You might ask why would you want to redesign an existing OEM Vortex Generator? The answer is simple. When OEM’s design a part/product the number one design consideration is producibility and cost. In a world where millions of vehicles must be produced in less than a year, parts must be able to be manufactured in a matter of seconds to meet production demands. This creates significant limitations on what an OEM to produce, which often results in sacrificing performance to improve manufacturability.

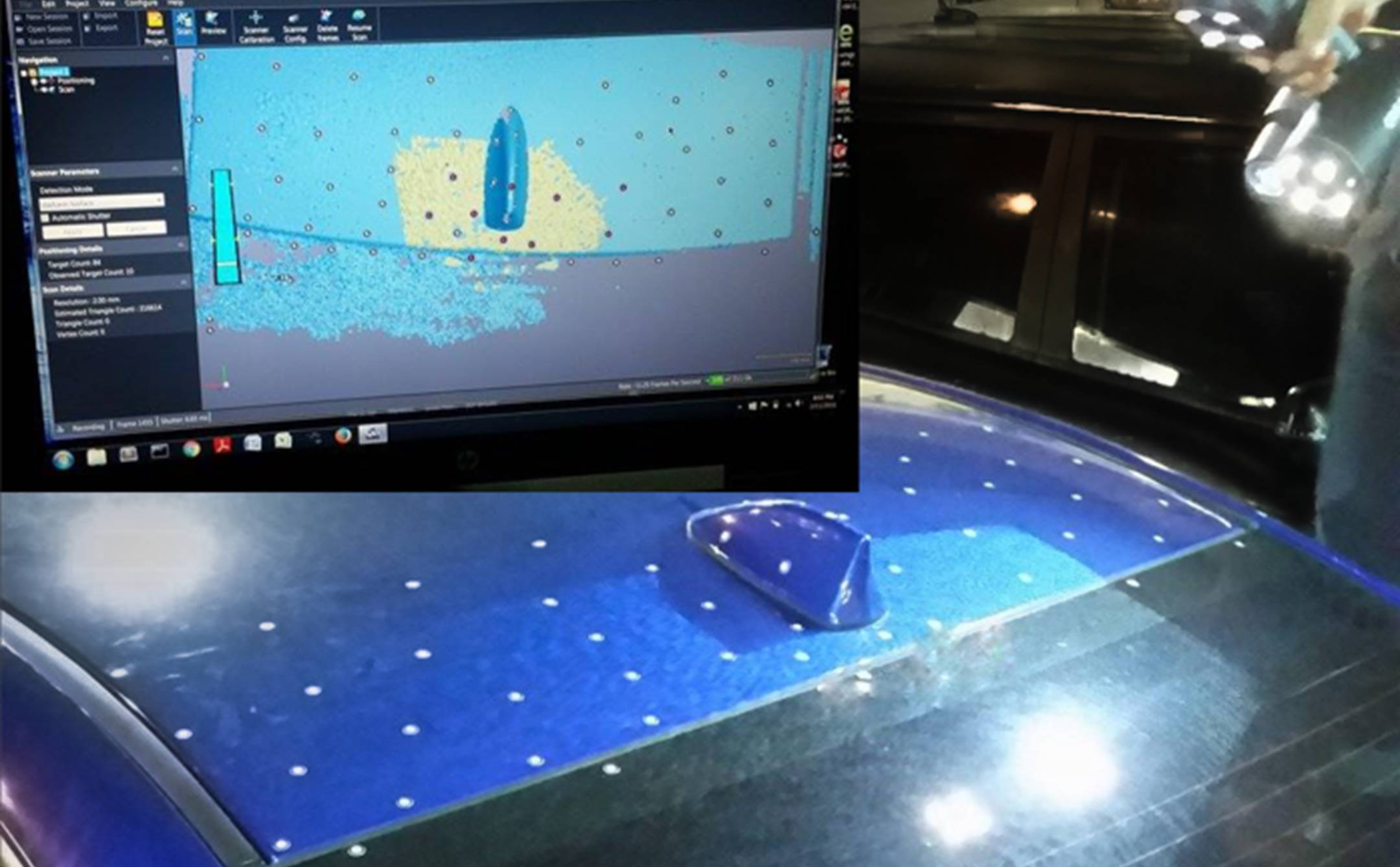

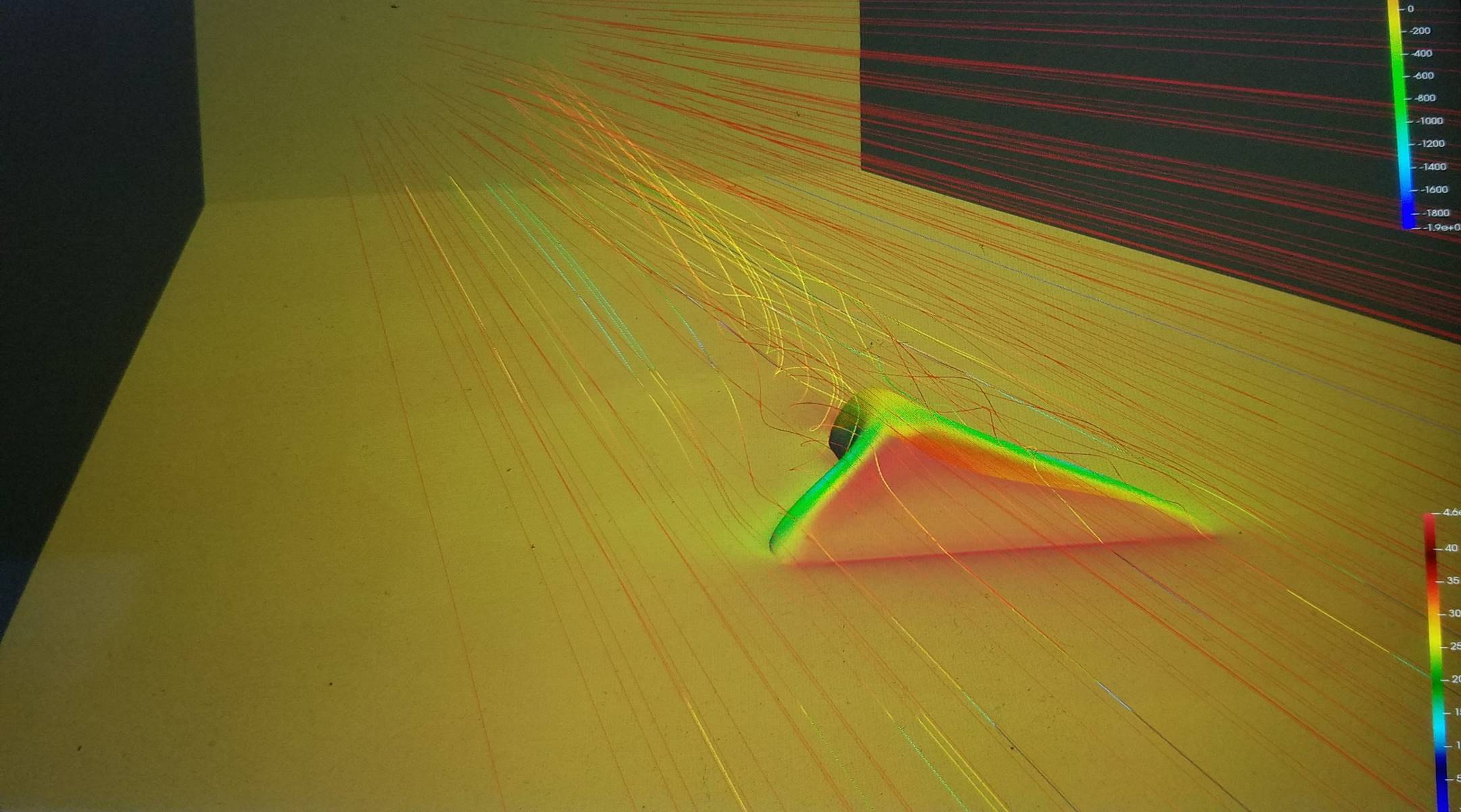

We at Renegade Motorsports saw a great opportunity to improve upon the OEM and similar aftermarket ABS plastic Vortex Generators currently on the market. Or primary design goals were to provide improved aerodynamics and to manufacture the product out of high quality composite materials. Once the demand is identified and the design goals are known the next step in the process is to define the product geometry. To shorten our design cycle and ensure our products have perfect fitment, we 3D scanned the rear roof section of the car to produce an accurate 3D model.